Good performance

- Smaller step angle and higher flow control accuracy

- Unique stop mechanism for lower running noise

High reliability

- Durability up to three times the industry standard

- Using automotive grade electronic components, safe and reliable

- Multi-dimensional evaluation and validation based on vibration, temperature and humidity

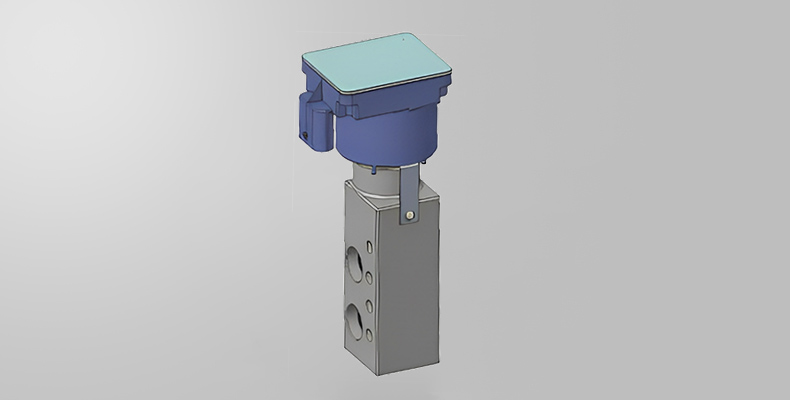

With integrated chip and more compact structure

Software design

- With layered architecture design, comply with vehicle specifications

- Precise control of small opening flow based on software compensation

- Using UDS fault diagnosis processing system

The main function is to throttle and depressurize the medium in the system so that the medium reaches a phase change, so as to carry out cold and hot exchange.

The suction superheat control system is composed of electronic expansion valve, pressure sensor, temperature sensor, controller, when working, the pressure sensor will evaporator outlet pressure P1, temperature sensor will compressor suction superheat transmission to the controller, the controller will signal processing, and then output instructions to act on the electronic expansion valve, the electronic expansion valve through the control of the stepper motor, the valve to the required position, to ensure the appropriate amount of liquid supply and suitable superheat.

Custom packaging can be provided to meet any need, please contact KESENS Engineering for details.

|

ITEMS |

PARAMETER |

| Communication Method | LIN2.1 |

|

Valve Port Diameter |

1~2.5mm |

| Working Medium | R134a,R234yf,R410A;PAG&POE Oil |

| Ambient Temperature | -40℃~+120℃ |

| Temperature Range | >-12℃~+80℃ |

| Operating Voltage | DC9V~DC16V |

| Rated Voltage | DC12V |

| Rated Current | < 0.35 A |

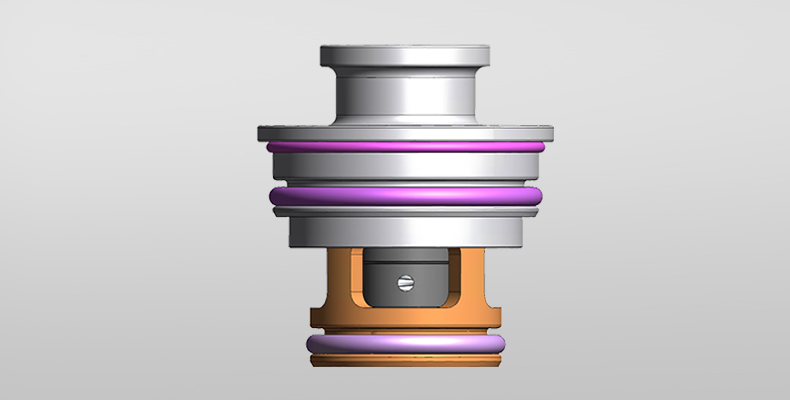

| Coil Drive Method | Stepper motor |

| Drive Frequency | 100PPS |

| External Leakage | ≤1.5g/y @ 3.5MPa |

| Internal Leakage | ≤100ml/min @ 1.03MPa |

| Compressive Strength | 5.4MPa |

| Burst Pressure | ≥10.6MPa |

| Insulation Resistance | ≥10MΩ @ DC500V |

| Degree Of Protection | IP69 |

| Lifetimes | >200k cycles |

| Open Valve Pulse | 38±15p |