Good performance

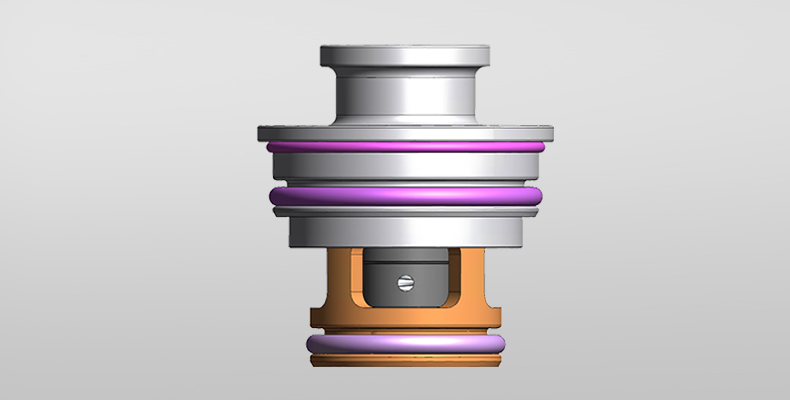

- Direct drive of the motor for feedback on the spool position.

- It can replace 4 SOV valves, which greatly reduces system costs.

High reliability

- Using automotive grade electronic components, safe and reliable.

- Multi-dimensional evaluation and validation based on vibration, temperature and humidity.

With integrated chip and more compact structure

Software design

- With layered architecture design, comply with vehicle specifications.

- Precise control of small opening flow based on software compensation.

- Using UDS fault diagnosis processing system.

The CO2 directional four-way valve realizes the mutual conversion between refrigeration and heating by changing the flow direction of the refrigerant in the system pipeline.

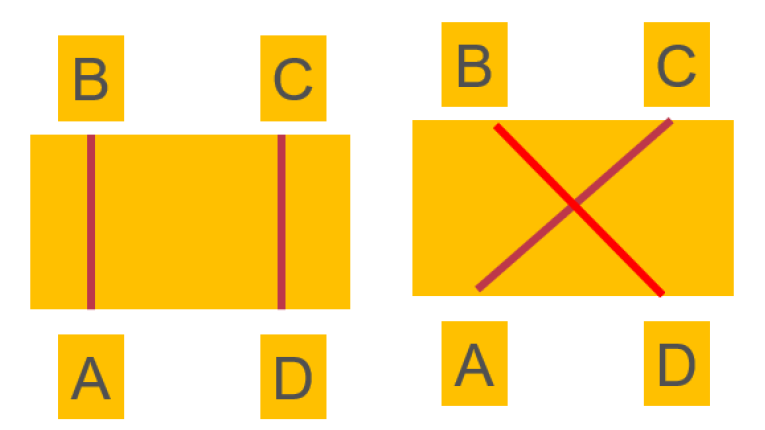

When the air conditioner is in the refrigeration state, the four-way valve is not energized (initial state),the four-way valve is in the state of AB connection, DC connection, the refrigerant is compressed by the compressor into high temperature and high pressure gas, through the A port of the four-way valve, discharged from the B port, into the outdoor heat exchanger (condenser), after the condenser absorbs cold and heat release, it becomes a medium temperature and high pressure liquid, after passing the expansion valve, it becomes a low temperature and low pressure liquid, after the indoor heat exchanger (evaporator) endothermic and cooling action, it becomes a low temperature and low pressure gas, through the four way valve D port, Return to the compressor from port C and continue the cycle.

When the air conditioner is in a heating state, the four-way valve is energized, the motor drives the valve core to move, so that the AC is connected, DC is connected, the refrigerant is compressed by the compressor into high temperature and high pressure gas, through the A port of the four-way valve, discharged from the C port, into the indoor heat exchanger (condenser), after the condenser absorbs cold and releases heat, it becomes a medium temperature and high pressure liquid, after the expansion valve becomes a low temperature and low pressure liquid, after the outdoor heat exchanger (evaporator) heat absorption and cooling action, it becomes a low temperature and low pressure gas, passes through the four way valve port D, and returns to the compressor from port B , and continue the loop.

Custom packaging can be provided to meet any need, please contact KESENS Engineering for details.

|

ITEMS |

PARAMETER |

|

| Communication Method | LIN2.1 | |

|

Valve Port Diameter |

8mm | |

| Working Medium | R744&PAG | |

|

Ambient Temperature |

-40℃~+165℃ | |

| Temperature Range | -40℃~+105℃ | |

|

Operating Voltage |

DC9V~DC16V | |

| Rated Voltage | DC12V | |

|

Rated Current |

< 0.5 A | |

| Coil Drive Method | Stepper motors | |

|

Drive Frequency |

100PPS | |

| External Leakage | ≤1g/y @ 10.5MPa | |

|

Internal Leakage |

≤100ml/min @ 10.5MPa | |

| Commutation Differential Pressure | ≥5MPa | |

|

Maximum Working Pressure |

17MPa | |

| Burst Pressure | 34MPa | |

|

Valve Opening Time (Off - On) |

11.6s | |

| Flow Resistance | Pressure loss≤100kpa | |

| Insulation Resistance | ≥10MΩ | |

| Lifetimes | >10K cycles | |